Written by William Sampson

sustainable alternative for ebony

Decreasing supplies of ebony have sent companies scrambling for alternatives, particular makers of musical instruments, where ebony is prized for its jet-black color, smooth polished luster, and durability in use.

Less than ethical harvesting practices in some places led to ebony from the island of Madagascar being put on the Convention on International Trade in Endangered Species (CITES) list. Some instrument makers such as Taylor Guitars have tried to promote using responsibly harvested ebony products streaked with lighter colors as an alternative. Other woods, such as maple and rosewood have also been used for fingerboards, but they aren’t black.

Now, Thermalwood Canada has introduced a new product called Obsidian Ebony that uses thermally and chemically modified maple to substitute for ebony. I was anxious to try it, and they sent me a sample pack.

Testing our sustainable alternative for ebony

Initial impressions

At first glance the Obsidian Ebony looks a lot like ebony straight off the saw. A consistent cool black color permeates the wood. It also feels dense and heavy like ebony.

I initially took a hand plane and saw to the wood to see how it felt in working. It planed and cut well, but did not readily reveal the instantly polished surface I am used to with regular ebony. I had a guitar project I was working on, so I figured that would be a good test

Planing the wood

First step was to plane a fingerboard blank down to the thickness I needed. Putting the blank through a power planer revealed a nice smooth, consistent black colored surface, but it also released a solvent smell. I did not find it too objectionable, but my wife and son really noticed it.

To create Obsidian Ebony, Thermalwood treats hard maple wood with a heat and steam process to chemically transform sugars in the wood, making it denser, insect resistant, and darker. In addition, a monomer infusion process ensures the black color throughout the wood. I suspect the solvent smell comes from that infused monomer.

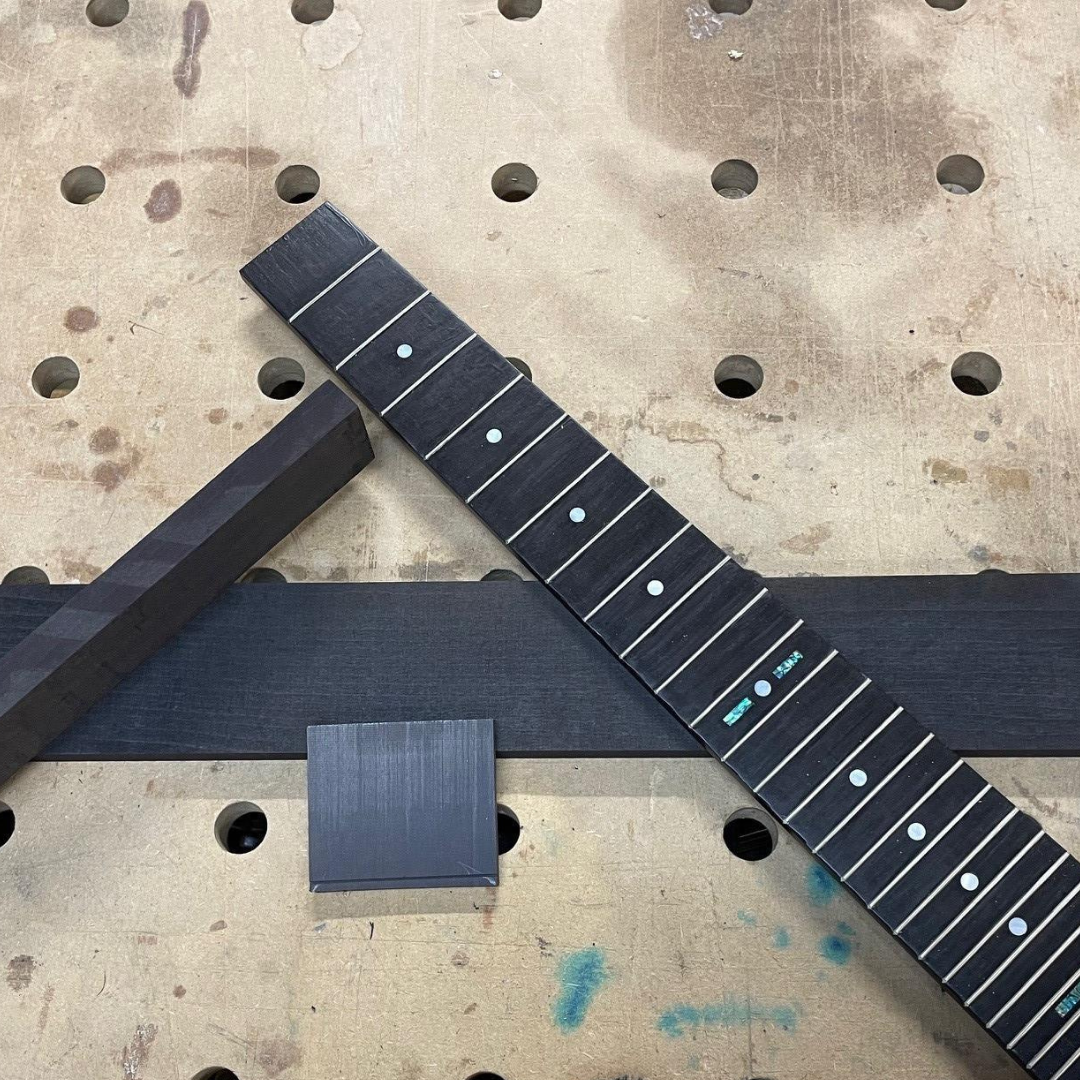

Making a fretboard

I cut fret slots in the fingerboard with a CNC router and also cut pockets for inlay dots and dashes. All the cuts were very clean and produced results just like I would expect from ebony. Fret holding was very good, and inlays were installed with cyanoacrylate (CA) glue. I didn’t notice any smell while cutting on the CNC machine or using a bandsaw to cut the final tapered shape of the fretboard.

I also tried various glues on samples. The company recommended epoxy, but I also got good results with CA glue, PUR with applied moisture, and even aliphatic resin glue.

I could not get the natural polish finish that is so characteristic of natural ebony without applying a surface finish to the wood. I will continue to experiment.

Although Obsidian Ebony does not perform exactly like natural ebony, it is a reasonable contender as a substitute and worth trying out for your application. Learn more at thermalwoodcanada.com.