thermal

modification

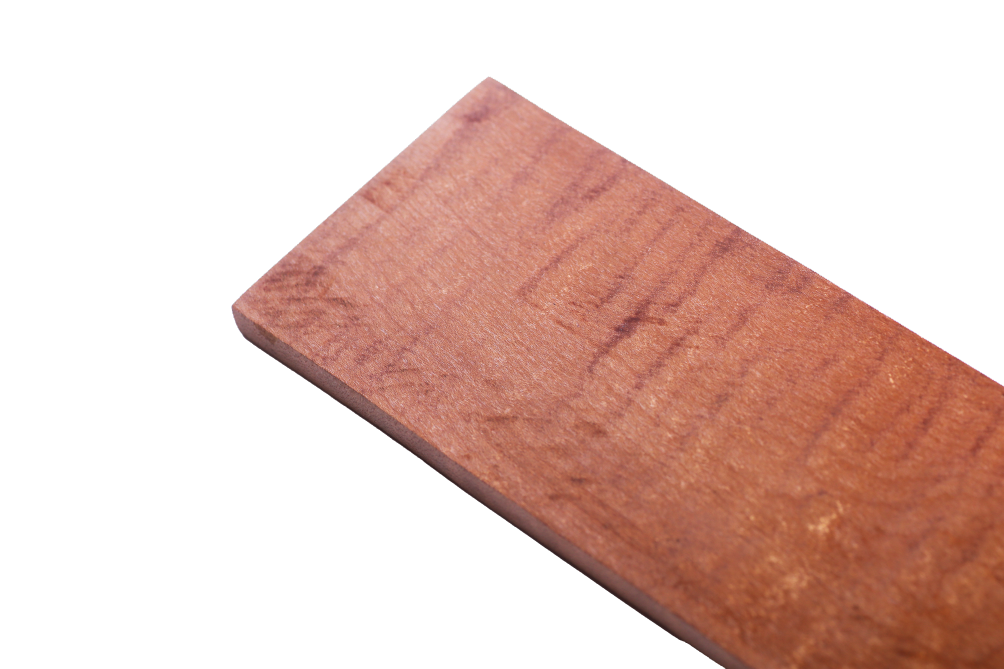

ThermalWood Canada prides itself on being a leader in the thermal modification manufacturing of wood products. Our in-house thermal modification process has been studied for many years, yet is simple at the base. Using our specially designed kiln, the wood is heated at a precise temperature, essentially cooking the lumber.

This process changes the characteristics of the wood. Notable advantages include:

- durability and stability

- Improved dimensional stability

- Decay and Insect Resistant

- The high heat chemically transforms sugars in the wood, making the wood unattractive to harmful insects, and acts as a barrier against decay caused by humidity and other water damage. A great choice for outdoor or indoor uses where high humidity is present.

- exquisite appearance

- Uniform darker coloration throughout the thickness of the lumber.

- green process

- Using only heat and steam – with no added chemicals during the process – we offer the consumer a green alternative solution in a diversified market.

our clip system

ThermalWood Canada has the sole rights to manufacture state-of-the-art GRAD clips (outside of France) to create an easy, DIY installation of your hardwood decking and cladding. The clips are made of POM (polyoxymethylene), which is one of the highest performing plastic on the market, the same to manufacture soles of ski boots.

- Save up to 50% on your installation time

- Invisible results: no need to drill through your wood, meaning no splinters

- Pre-set spaces between clips means perfect installation everytime

elevate your project with thermalwood

We want to know all about your project. Big or small, it doesn’t matter. ThermalWood Canada is here to bring your project to life. But in order to do that, we’re going to need some information from you so we can give you the most accurate feedback we can. So, click below, explain what you have in mind, and let us tell you how our products will elevate your project to the next level.